" We are constantly developing new projects and initiatives to harness the full potential of emerging technologies, all aimed at achieving our ultimate goal: the SMART FACTORY. "

OUR VISION

To enhance manufacturing efficiency and flexibility while ensuring consistent and reliable processes by leveraging data analysis, integrating intelligence into operations, and delivering the right information to the right people.

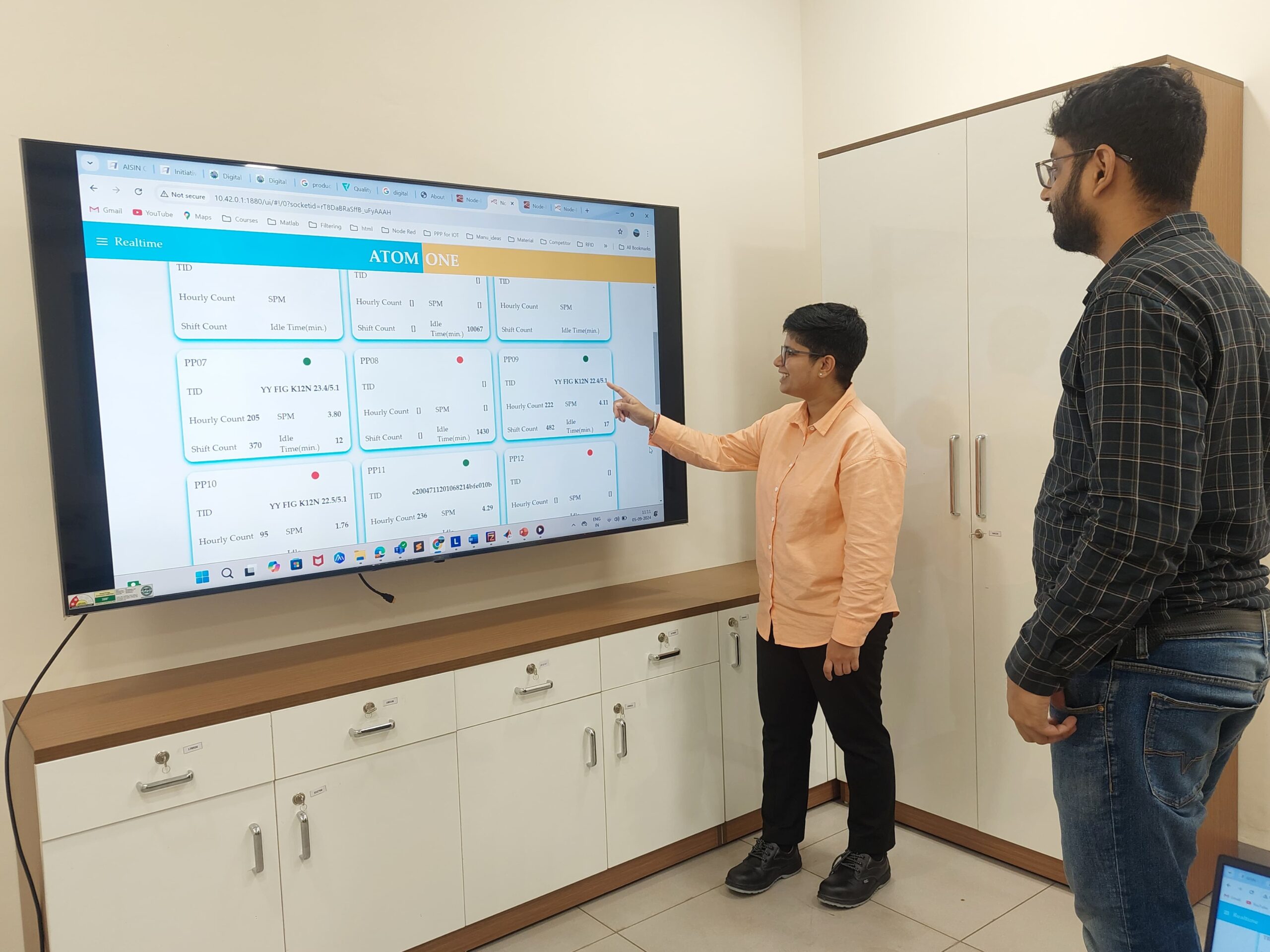

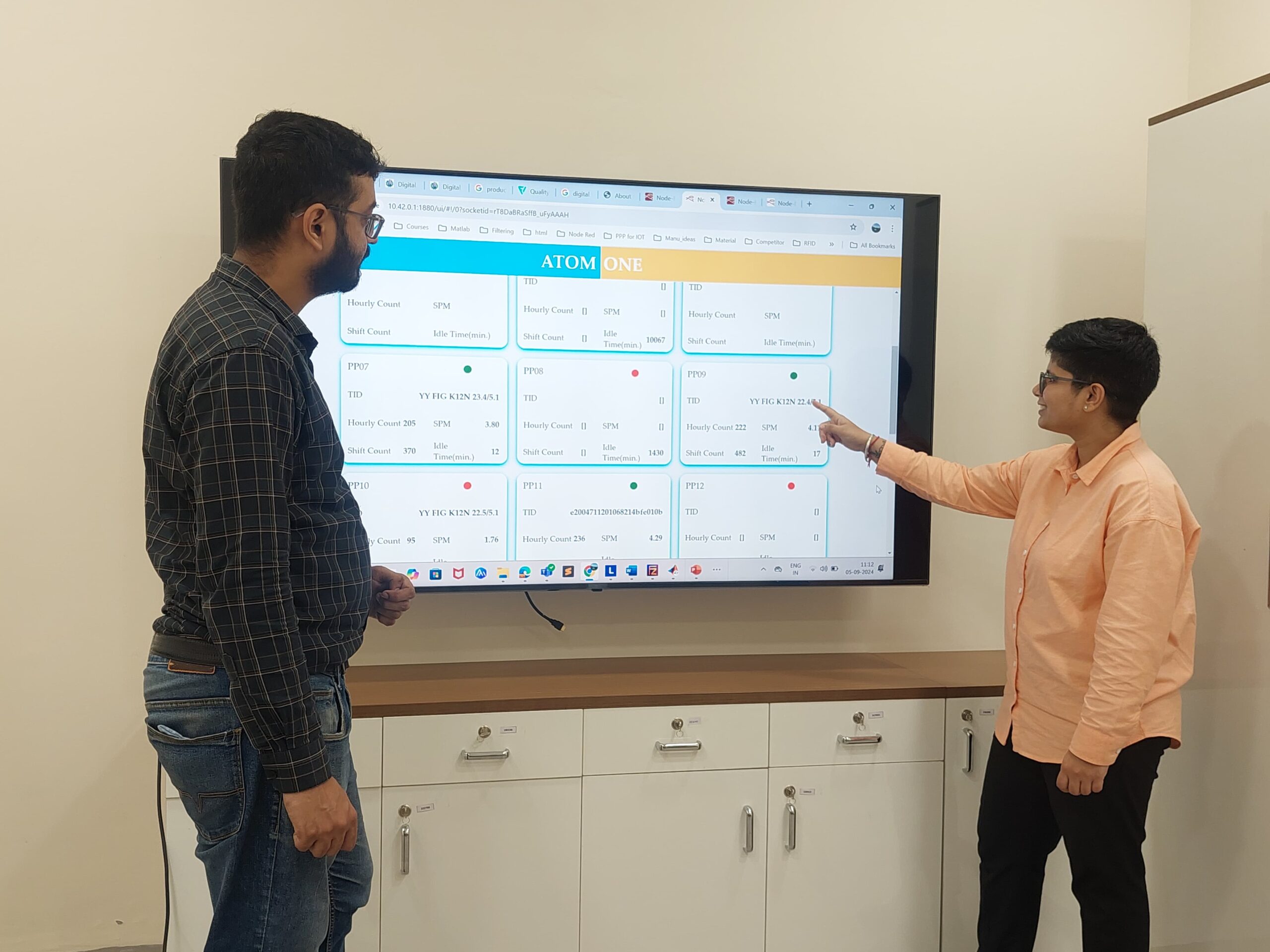

Our in-house IoT system integrates real-time production data into a digital platform to streamline and improve production management. By linking data from shop floor, we enable centralized and remote control of operations, aiming to reduce indirect business processes by FY 2026. This approach allows us to monitor on-site conditions in real-time, centralize plant administration, and control multiple machines, ultimately reducing management hours.

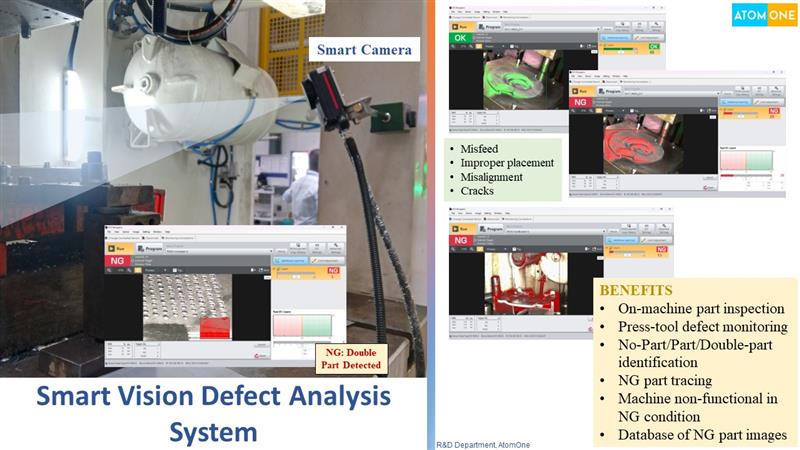

Key to our transformation is the Digital Transformation (DX) Factory, where data from production sites is collected, analysed, and the insights are applied back to the shop floor. We employ AI-driven machine vision solutions for rapid quality analysis and leverage Industry 4.0 technologies, including data analytics, connectivity, and human-machine interaction, to unlock significant value across our AtomOne factory network. By driving DX with IoT and data-driven decision-making, we are enhancing operational efficiency, quality, and productivity

Our DX initiative combines the physical and digital worlds, harnessing data to make informed decisions, enhance productivity, and develop top-tier products efficiently. The “AoT4.0” program brings together on-site employees and digital teams to re-engineer business processes using data insights.

15-20%

Machine Utilization Increment

8-12%

Operator Efficiency Increase

10-15%

Quality Improvement